FINANCE

Building an Economy in Low-Earth Orbit and Beyond

NASA’s decision to step back from low-Earth orbit leaves a space for private companies to step in and take advantage. Daniel Davies questioned the space-based manufacturing company Made in Space’s CEO, Andrew Rush, on how his company is profiting from opportunities in LEO and how, in the future, its technology will be used to turn humanity into a multi-planet species

By now you’ll have heard that NASA wants to go into cislunar and deep space, so having maintained a presence in low-Earth orbit (LEO) for the best part of 20 years, the US space agency has changed its focus to conquering Mars and the Moon. While its decision to vacate the International Space Station (ISS) and instead journey further than anyone has ever gone before signals a return to the explorative origins of the agency, it will also create opportunities for private companies to start making money by filling the NASA-shaped hole that will soon be found in LEO.

Phoebe Hugh, CEO, Brolly

For obvious reasons, the prospect of contributing to and profiting from a LEO economy is appealing to private companies, but NASA itself has also been unabashed in admitting that it wants private companies to step into the ISS. It knows that exploring deep space without getting the cost of the ISS (currently about $3 billion annually) off its books is virtually impossible, and equally it knows that giving access to its unique facility will allow private companies to pursue opportunities in fields as disparate as tourism, manufacturing and marketing.

In manufacturing, transporting materials into outer space can cost tens of millions to hundreds of millions of dollars, but the space-based manufacturing company Made in Space has already shown how it can reduce that cost, as well as support life on the ISS, by producing the necessary parts, tools and facility to effectively eliminate the need to launch materials from Earth.

Made in Space is just one company working to profit from going to space, and as Andrew Rush, president and CEO of Made in Space, explains it isn’t alone in seeing the potential of the LEO economy.

“The LEO economy is certainly something that people are thinking about and talking about more than they were five years ago. As Made in Space and other aerospace companies continue to develop technologies to industrialise space, we are seeing more people – companies and individuals alike – begin to think about how to commercialise LEO,” says Rush.

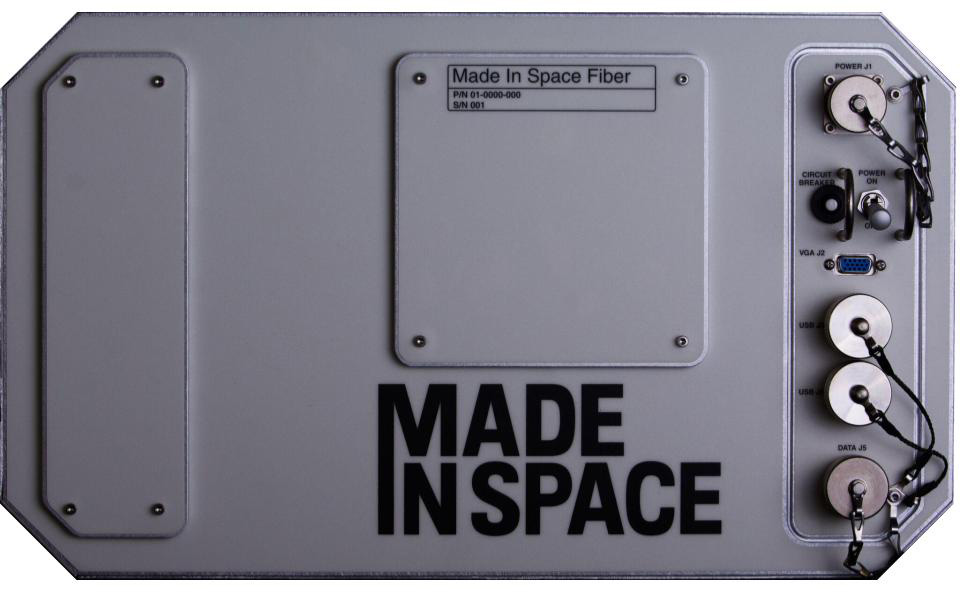

Testing Made in Space manufacturing aboard the International Space Station

Private companies making money from the burgeoning LEO economy owe a debt of gratitude to the work NASA and its partners have done in LEO and on the ISS. Made in Space is no different, and although the company was conceived back in 2010 to take advantage of the fact that no one had taken 3D printing technology and applied it to space, it was thanks to its collaboration with NASA that the company and its tech were able to thrive.

“Our founders were inspired by the possibilities of mankind living and working off Earth and exploring deep space. When the company started in 2010, they were looking at emerging, impactful technologies. At the time, 3D printing was just taking off and showing promise as a disruptive technology. So, we thought, what if we tried it in space - no one had done that,” says Rush.

“After extensive research aboard parabolic flights with NASA, under the Flight Opportunities Program, we achieved really breakthrough insight into how to make 3D printing work in space. In 2014, we built our first 3D printer for NASA and began operating it aboard the International Space Station.

“In 2016, we sent a commercial, second-generation version of the printer – the Additive Manufacturing Facility (AMF) – to the ISS, where it operates as the world’s only commercial manufacturing device in space. We had success early on, success that would not have been possible without the great opportunities NASA gave us and their faith in our team. We’ve continued to take what we learned during those early days to improve our core additive manufacturing in-space technology for current and future projects.”

Image courtesy of Made In Space

Benefiting from the low-Earth orbit economy

Having benefitted from NASA’s assistance, the next stage for everyone from Made in Space to SpaceX, is for private companies to take the lead and develop an economy that relies solely on commerce. But how exactly does a company like Made in Space make money from in-orbit manufacturing?

Well for now, Made in Space profits from building structures in space to be used both on Earth and off this planet. Using its AMF, Made in Space provides hardware manufacturing services to NASA, the US National Laboratory and commercial customers. AMF has been used to print items like medical tools designed by doctors or tools to be used around the ISS, and the technology can offer faster delivery times and customised parts, while also requiring limited human interaction.

“Manufacturing in space enables us to achieve greater cost savings versus having to launch expensive cargos from Earth and make more efficient and optimised exploration of space possible,” says Rush.

“Manufacturing in space enables us to achieve greater cost savings.”

“The ISS has tons of cargo space taken up with spare parts that will never be used. NASA and other space agencies need to have these parts on location in case something fails, because to send up a part from Earth can take several months. If those astronauts have an integrated manufacturing solution with a digital catalogue of all the spare parts though, they do not have to use such a significant amount of their available volume to store spare parts. They simply use the manufacturing facility to manufacture the part they need, when they need it. When they’re done, the part can be recycled back into feedstock and used again by the printer to create something entirely different.”

For Earth, Made in Space has plans to manufacture fibre-optic cable that isn’t as vulnerable to signal loss, as it would be if it was built on Earth. Additionally, because the fibre is so expensive to make on the ground, Made in Space will be able to profit from sending large quantities of high-grade optical fibre to Earth.

“Microgravity can actually present us with a manufacturing environment that’s more favourable than Earth,” says Rush. “This year, we’ll be manufacturing an exotic optical fibre called ZBLAN onboard the International Space Station. The lack of gravity allows us to create a much more capable material than we can achieve when we manufacture in a gravity-rich environment, such as Earth.”

Manufacturing the infrastructure we need to become a multi-planet species

Ultimately though, Made in Space has much grander plans in mind. The largest manmade structure in space today is the ISS, which took tens of billions of dollars and a decade to construct, but with its in-development Archinaut technology, Made in Space believes it can deliver the next generation of large-scale, off-world structures by using a combination of 3D printing and robots to build them for less and without the need for on-the-ground human help.

“On a larger scale, using our Archinaut technology, we can manufacture spacecraft and satellite systems in space much larger than what is currently possible,” says Rush. “Right now, everything we send to space has to either fit inside a relatively small launch vehicle, or be sent in multiple pieces and (very expensively) attached together using astronaut extravehicular activity, where the astronauts actually have to assemble the spacecraft out in the vacuum of space. Archinaut enables the manufacture and assembly of spacecraft and satellites in space.

“The ultimate goal of Made in Space is to develop the technologies that enable humans to sustainably live and work in space.”

“Archinaut is a manufacturing system with extended structure 3D printing and robotic capabilities. The extended-structure 3D printer manufactures the parts in various materials and geometries, and the high-precision robotic arms assemble the pieces together. This technology allows us to build spacecraft and satellites in space so that we no longer have to account for the tough launch requirements.”

Looking even further into the future, Made in Space is already working on technology that can push it beyond the LEO economy it is currently part of, and Rush says it is already working on a number of technologies that will be important on deep space missions to asteroids, other planets and moons. Like NASA it wants to go into cislunar and deep space, where it will manufacture the infrastructure we need to become a multi-planet species.

“The ultimate goal of Made in Space is to develop the technologies that enable humans to sustainably live and work in space,” says Rush. “To that end, we most definitely expect to see our technology used in the construction of space habitats, roads and buildings on other planetary bodies in the future.”

Image courtesy of Made In Space

Main image courtesy of NASA